First up is all things copper. I made a few of my copper birds following the original one that I made for the arts festival (sorry to say that the original has suffered from a few spectacular crash landings and is now parked in a corner while I decide what to do with it. Demand for these birds has continued, and to date I have made eight, with another one due to be finished next week. They are a bit fiddly to make with my fat fingers, and the heads are always a bit of a challenge, so every one is different in some way to its predecessors. I like making them, but a bit of a change is in order, so....

... I made some flowers out of copper instead. These are much easier to make than the birds and the colours that the copper takes when heated up seem to suit flowers well - colours vary from a pale straw through orange, then purple, bluish silver and last a pale gold. A bit more heat turns the copper a pale pinky gold, and there it stays no matter how hot it gets. Dipping the piece in vinegar for a few minutes cleans off the colours, and I have accidentally produced some interesting patterns and textures by heating up a cleaned piece while the vinegar was still on it. It seems that the oxide colours are refractive, which is why they go dull when the piece is handled - greasy fingers reduce the refraction effect - or when sprayed with a protective laquer.

Flowers are great, every one is different so a lot more creative satisfaction in making them. So much fun that I tried a different subject - butterflies. These are even easier than the flowers and the wings show off the colours really well. The wings are copper foil, of course, the bodies are a bit of brass rod with the ends rounded off in the lathe, and the legs are made from fine electrical wire stripped from some old cable that I had hanging around. Recycling? I do it every day :-)

Flowers are great, every one is different so a lot more creative satisfaction in making them. So much fun that I tried a different subject - butterflies. These are even easier than the flowers and the wings show off the colours really well. The wings are copper foil, of course, the bodies are a bit of brass rod with the ends rounded off in the lathe, and the legs are made from fine electrical wire stripped from some old cable that I had hanging around. Recycling? I do it every day :-)A potentially good development has been the finding of a 'artisan studio' to put some of my stuff on display. She has some of the flowers and butterflies, as well as one of my jewellery boxes and a shoji-style table lamp. Its early days (the stuff has only been there for a week) but we may see some of the pieces march out the door as Xmas approaches. Watch this space.

|

| The original wall lamp |

Jon and Katie liked the lamp, so I made them a pair in light oak for the bedroom. My lamp is switched on and off by the Arduino/Home Easy control box, and it doesn't have a switch of its own, but the new pair have a pull-cord switch built into each one.

|

| Jon's oak wall lamps |

|

| The new hanging lamp |

There's been some action in the garden as well, in the form of badgers. I like to see them shambling around, but they are particularly fond of greengages which fall off the tree at the end of the garden. Badgers make a JCB look like a wuss when it comes to digging, so keeping them out is a bit of a challenge - they seem to come in at one point and then look for another way out, and if there ain't one handy, they set to work and make one. In the past we've used rags soaked in Jeyes fluid which stopped them (while making the garden stink like a Portaloo), but this didn't work this time and nor did the creosote applied by the Man At The Back. A detailed search of the interweb yielded the idea that badgers are put off by the pee of larger animals, including humans, so a few trips into the bushes at dusk each night and it seems to have worked! Have to repeat the treatment after rain, but I'm hoping that if they get used to finding their dinner somewhere else that they will not return. Watch this space, I'm not particularly looking forward to the nightly application in January...

Now that the copper and wood dust has settled I've made a new start on the engine. I've been trying to find a couple of old paint cans to use as the basis for a small furnace to make the castings and only recently managed to locate some, thanks to George at the pub - George is a true son of Somerset, and although I grin and nod when he talks to me I have absolutely no idea what he is saying, so a 2 way conversation is a bit tricky. I've made a couple of simple patterns and will try some melting as soon as the weather dries up a bit. In addition, I've cashed in the £25 reclamation yard voucher that I won at the Arts Festival and secured a couple of cast iron sash weights (ideal for the cylinders for the new engine) and a small Siddhartha statue for the garden.

|

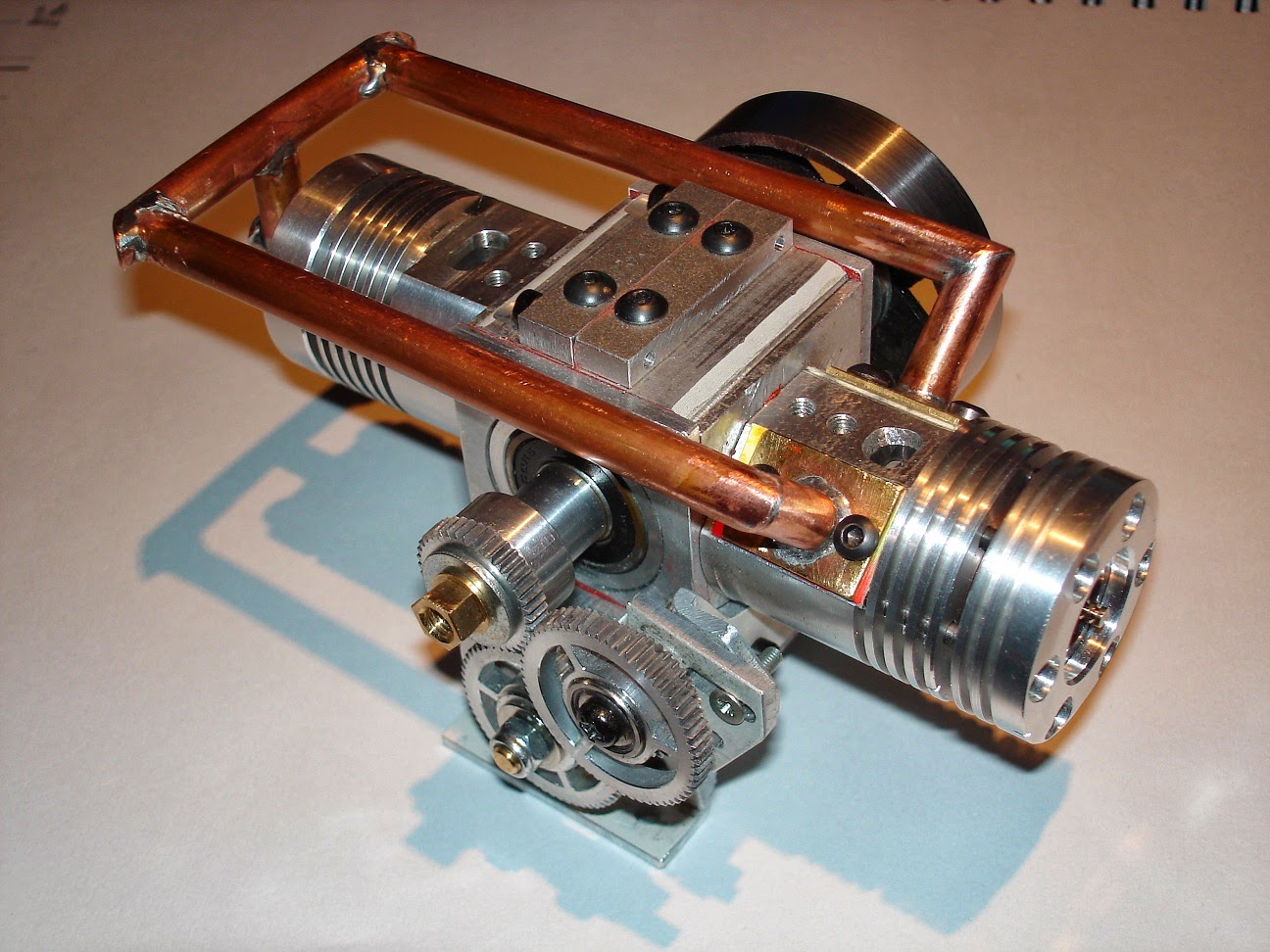

| New oil pump for The Beast |

The new pump is a big 'un. The body is machined from a 20mm thick block of alloy, and it has a pair of 28mm diameter glass filled nylon gears to do the pumpage. The tolerances are pretty tight, otherwise the gears just stir the oil without pumping it, and one of the gears was made slightly off centre with its bore so I had to do a lot of fettling with swiss files to get the gears to mesh properly and spin in the housing. The drive shaft has proper bronze bushes for bearings, and a real oil seal to keep the juice from squirting along the shaft. Finished it today, assembled and immersed it in a tub of oil and cranked it over with the power drill (note to self - use the slow speed next time). Once I cleaned up the mess I was quite pleased, it produced an impressive jet of oil out of the outlet and didn't seem to leak. Hooray!

I started tae kwon do training again a couple of weeks ago, after more than 18 months of doing very little, but I think I'm going to have to look for a new club - the old one only has 5 or six people training and unless they round up a few more punters its going to fold. The last session I went to, I was the only one there, so I'm going to check out the club where Jon trains next week. On the plus side, I managed to survive the training sessions with nothing worse than a bit of stiffness. My martial arts training is taking a bit of a dive overall, as my tai chi instructor is heading off to Bali at the end of the month to start a sailing school there, and I don't think the replacement instructors are anywhere near as experienced, unfortunately, and there's only a few students so I don't expect that one to last long either :-(

And last, went karting last weekend. Had a pretty good day, didn't win anything but managed an 8th place out of 13 and stayed with a couple of the boys for most of the laps. Then came the final, and with it the rain. Just enough time to slap on the wet tyres before the race and we were off - last time I drove in the wet it was like driving a speedboat with a broken rudder, but the changes I made to the front track a few months ago made the old girl a bit easier to handle and I managed to go reasonably quickly without falling off. I got overtaken on the straight a couple of laps before the end while drifting over to the right to get a better run at the next corner and just in time saw the other punter out of the corner of the visor as he took to the grass. Wet grass at 60-odd mph is not a good combination but with a few wild swings he managed to get it back on the black bit, an excellent save on his part. It was so wet, and getting very dark, that they stopped the race a few laps early - thank goodness for the wet suit I was wearing, and for the dry clothes that I always take with me.

That's pretty much the news for now. Next month I hope to be able to report progress on the casting malarkey and if that goes OK I will be machining cylinder blocks, crankcases and pistons like a man possessed. Hoo-raw