First up, my personal shout to Stephen Sutton. Unless you live under a rock you will all have seen mention of this guy on the news, he was diagnosed with bowel cancer at 15, and died this week at the tender age of 19. What makes him special is the way that he lived those four short years, and his cheerful positive attitude right up to the end. His story is here -

https://www.facebook.com/StephensStory

He devoted his time to raising money for a teenage cancer trust, and started with a target of £10,000. The last time I checked, he had impressed people so much that donations were up to around £3.7 million. I'm not sure if they are still accepting donations, but if they are please honour his memory by sending them a few quid, the collection web site is here -

https://www.justgiving.com/stephen-sutton-tct

He was an inspiration to us all and I salute him. Vaya con su dios, Stephen.

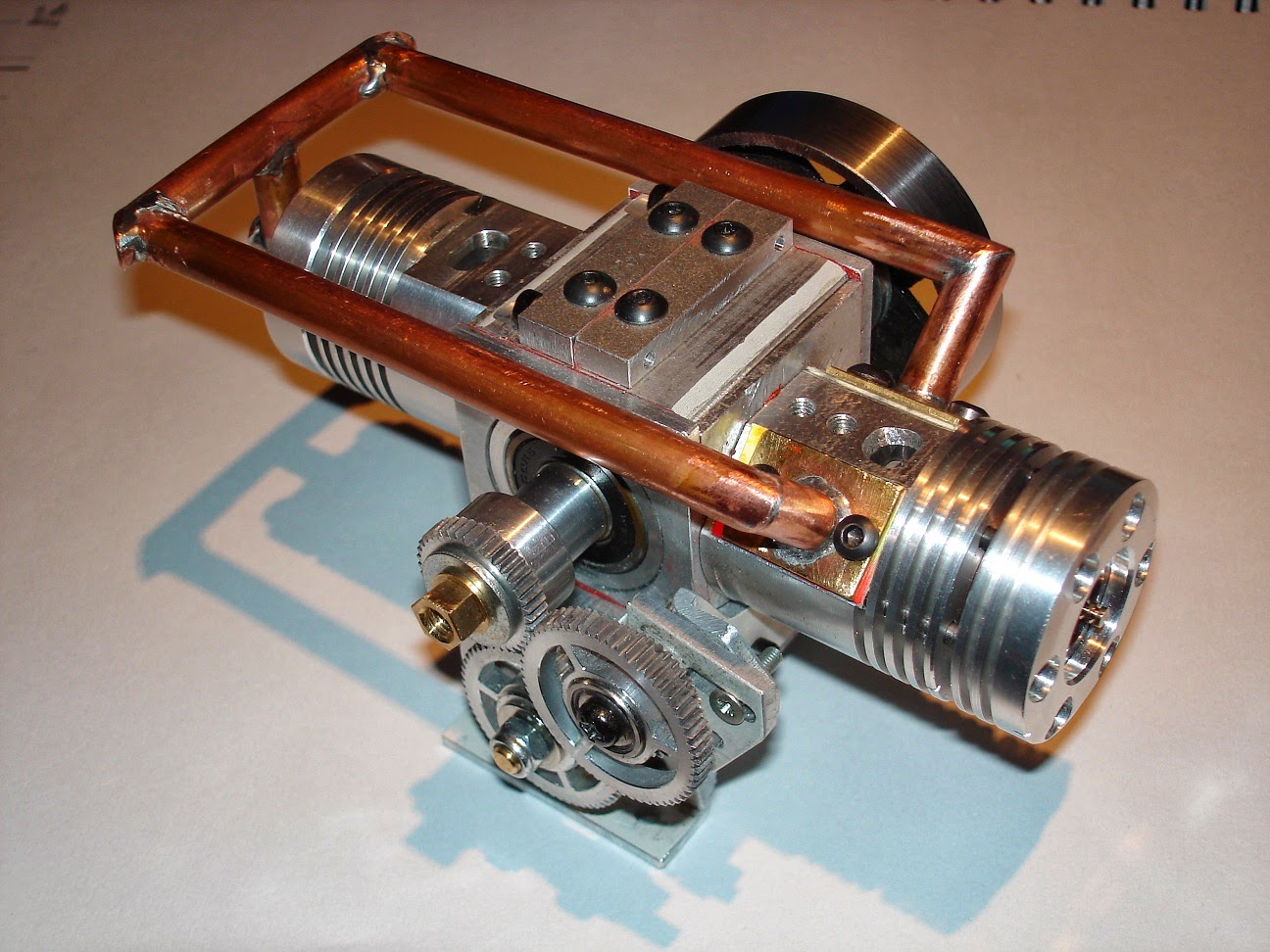

And now: The Beast

This is the new engine, woohoo! Like the last one, its my own design although based on a real engine, and this one will be made a bit better to ensure that there is no repeat of the crankshaft waggling that we had on the first one.

First: what makes it different? The engine will be a 2 stroke, but will not have conventional cylinders - instead, it has a pair of cylinders mounted horizontally, with a pair of opposed pistons in each. One piston operates the exhaust ports, and the other the inlets, and they are linked to the crankshaft by means of a set of rocker arms and double conrods. To make sure that the red-hot exhaust gas doesn't blow out of the carburettor (now THAT would be worth seeing!) there is a supercharger that blows the fresh mixture into the cylinders and forces the exhaust out through the right holes, and by offsetting the crankshaft slightly this can be used to slightly supercharge the cylinders. This is the 'real' 3 cylinder engine on which this design is based with the side covers removed to show its innards.

It was made by the Rootes Group back in the sixties and for its day it was a stonker in terms of performance and fuel efficiency (though some of the trucks that used it had a very short exhaust pipe that exited under the front bumper, and on a long hard pull up a steep hill the bits of red hot carbon flying out of the exhaust would often set the hedges on fire). It was also prone to running backwards if you were careless with the clutch, with the inevitable screaming runaway culminating in a spectacular explosion. It was a diesel, but mine will run on petrol with real miniature spark plugs so that I can control when and for how long the plugs fire.

So far, I havn't made very much. I have done a huge amount of designing and drawing, and now know what its going to look like, and have made a start on some of the oily bits. The first is the crankshaft, since this is the bit that was pretty unsuccessful last time and I need to learn from those mistakes. Most model engine builders make the crank from a solid hunk of steel and machine off probably 90% of the metal to produce a finished part. They also offset mount the shaft in a 4 jaw chuck on the lathe to turn the crankpins. Well, I don't have a 4 jaw chuck, and chewing off that much material seems like doing things the hard way, so mine is fabricated from bits like these.

I cut the six crank webs from 6mm steel plate and drilled them in a stack to make sure they are all the same. Two of these are welded on to the stub ends of the shaft to make two identical end pieces, and two more welded to another short shaft make the centre bearing section. The last two are pressed together using the crankpins to make the complete shaft. Sounds easy, but it was a pig to make (I have the wreckage of the first few attempts littering the bench to prove it). The offset crankpins make the two halves of the shaft asymmetric, and pressing the pins into the webs in the right place was a 'mare involving a special assembly fixture and a lot of careful work with the dial indicator. Once it was all pressed together, the clamping screws were tightened until they squeaked; all of the various oil holes drilled, and the crankpins permanently locked in place with hammered-in pins. The finished article was mounted in the lathe, where of course it wobbled all over the place, but I machined the three main bearing journals down so that they all ran true and Robert is your Mother's brother. Carefully blow the swarf out of the oilways with compressed air, and that bit is done.

I've also made a stack of bronze bearings. Once again, the traditionalists take a very very expensive chunk of phosphor-bronze and machine almost all of it away to produce a thin sleeve bearing. Instead, I used readily available bronze Oilite bushes (cost a few pence each) and split them lengthwise with a Dremel cutting disc. Solder the split edges together, turn the inside diameter first and press on to a mandrel to skim the outside, then de-solder to make a pair of split shells. Worked a treat, the picture below shows the first pair of big ends in the prototype con rod..

I've also made a set of conrods and rocker arms as prototypes and am in the process of making a full set based on these. The rods are made from 6mm steel plate, welded up to make a 'fork' shape and then bored at both ends. The crankshaft end has to have a detachable cap and split bearing so that it can be assembled and taken to bits if needed. The rockers take most of the force in this engine so they have to be pretty massive - they are made from three steel discs, welded to a pair of 3mm thick steel ribs on a jig, and then bored for bearings.

There's still loads to do, this isn't going to be a quick one by any means. Next up will be some of the ancilliary bits like the oil pump and supercharger, and then I'm going to try my hand at casting the engine block, cylinder jackets and pistons. Keep a look-out for smoke to the south west, and keep the animals and children indoors for a while.

Next up, some karting. Took the old girl out for a race last Sunday, and I'm pleased to say I managed a bit better. Last month I was awful, way behind the rest of the gang, and when you are just banging around on your own its nowhere near as fast as if you are chasing someone. It also gives you too much time to dwell on how much your ribs and forearms hurt, or how your head is just flopping around from the G force by the end of the day.

This time it was much better. Equipped with my first new set of tyres since last August, I put in some half decent lap times and stayed with the pack for most of each race, while changing the carburettor jet and playing with tyre pressures seemed to help as well. Got pulled in by the scrutineers at the end of the last race and he mentioned that the variable exhaust valve was set around 2mm too far out - doesn't sound like much but on these little engines that may have a major impact, so I've set it up according to the instructions and we'll see what difference it makes. Next outing is a practice day at Dunkeswell in July, no racing in June as I will be in Spain :-)

Just to prove I don't spend all my time hammering metal, I made a coffee table for Sean and Mad. Its a pretty simple design, although lots of agonising over dimensions to make sure that the proportions came out right. Its made in english oak, hard work to cut because the grain is very short and the wood is so hard, but when its finished the texture and colour of the wood is fab-u-lous.

It has a drawer that blends in with the sides, and a hidden finger pull and self-closing hinges, but it doesn't have the built in wireless charging mat; the hidden USB ports and the blue LEDs that were originally on the build list, probably just as well. I'm really pleased with it, probably going to ask to borrow it back for the -tada! - trumpet fanfare....:--.

Middlezoy arts festival! The village is running this two day event in July with all sorts going on, full details are on their web site here:-

http://www.middlezoyartsfestival.org.uk/

I am one of the artists exhibiting. I will have as many bits as I can muster on show - cabinets and boxes, as well as some engravings and maybe some other stuff - and I will be doing live engraving demonstrations. Lets hope that the weather is fine all weekend, and that de good lawd doesn't take exception to me being in the village chapel and visit us with a couple of thunderbolts, that would pretty much ruin the day.

Part of the festival is a garden art competition, and for this I shall be making a golden eagle, and a family of snails. More on this next time, or if you come to the festival you can see them for yourself!

Despite being retired and loafing about all day, every day, its time for a holiday so we're off to sunny Spain at the beginning of June. We're going back to La Herradura again, we know the area well and it should be a fine relaxing time with an apartment right on the beach and in easy stroll of the bars and restaurants. See you when we get back